Our metrological inspection services compriose a broad and comprehensive range of techniques from on-site data capture to data processing and delivery of measurements to analyse the failure, wear or distortion of mechanical components and/or assemblies.

The use of metrology testing is vital to ensure accuracy and repeatability in machined parts that can be used in applications around the world. The type of metrology testing tools used will depend on the equipment used in the production process and the parts that are manufactured.

Our solutions can be used to model the length, shape, position and size of defects or anomolies on infrastructure.

Your challenges, our responses

- Expert assessment of the existing situation

The challenge: to have access to high-precision (sub-millimetric) measurements.

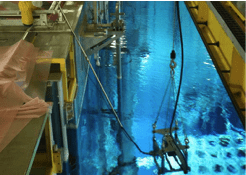

We conduct on-site contact or non-contact metrological inspections by tracking, probing or digitally scanning, depending on the precise nature of the project and operational conditions. Where direct measurement is impossible, we take high-precision impressions which are then scanned.

Our solutions

What sets us apart distinctively from competitors

- Our ability to acquire high-precision measurements regardless of:

- volume, length, shape and size

- complexity, weight, fragility

- material or colour

- Operational development engineering: innovative techniques and production of measurement robots

- 25 years of experience in metrology for leading industrial, nuclear, water company and other clients